Since 1836, EBERLE have been producing high-quality tools and strip steel products for industrial and technical purposes. Our products are renowned for their excellent precision, quality and maximum performance. With our extensive range of products, EBERLE is a respected partner and market leader in terms of quality for sawing metal and producing top strip steel products.

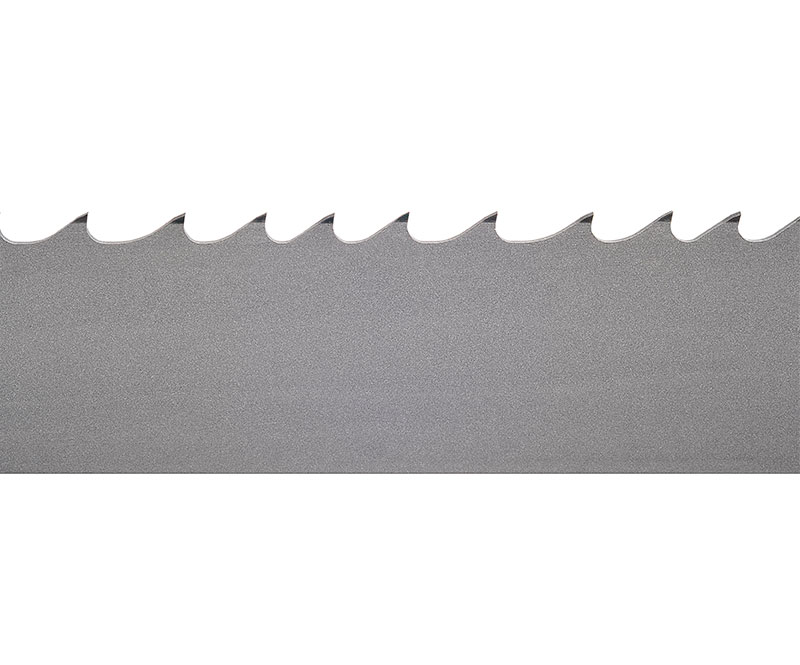

M42

M42

duoflex M42

duoflex M42 is a high performance, multi-functional bimetal band saw blade that is

characterized by its high wear resistance and long blade life. The blade is suited to

cutting almost all steel grades in workshops and serial production.

鋸切硬度參考:HRC ≤ 44度

應用範圍:成捆圓棒材/成捆並列方管材/成綑管材/並列鋸切/厚壁管材/整把角鐵/圓棒材/方柱/扁鐵/工字鋼

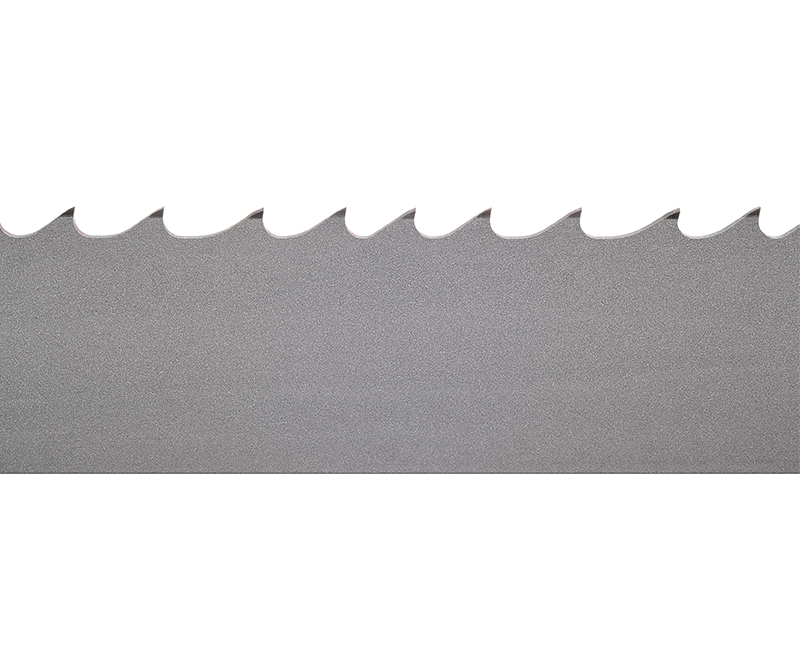

MX55

MX55

duoflex MX55

duoflex MX55 is engineered for use in heavy cutting applications. The cutting

performance of the high speed steel teeth is substantially increased through alloying

elements such as Cobalt and Tunsten.

鋸切硬度參考:HRC ≤ 49度

應用範圍:成捆圓棒材/成綑厚管材/並列鋸切/厚壁管材/圓棒材/方柱/扁鐵/工字鋼

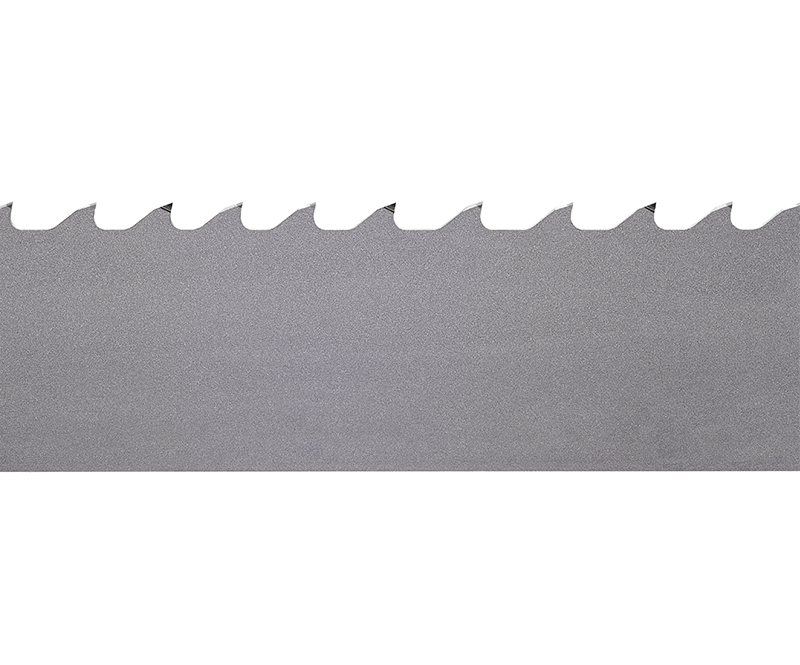

CT4

CT4

CT-flex 4000

The carbide-tipped blades with CT4 geometry cut a variety of materials with low

machinability including Titanium alloys, Inconel, and nickel-based alloys.

Additionally, the range extends to cutting Aluminum and other non-ferrous metal

applications where short cycle times are required. The teeth are engineered to

divide the cutting area over several cutting teeth, so the blade runs extremelysmoothly.

鋸切硬度參考:HRC ≤ 65度

應用範圍: 圓棒材/方柱/扁鐵

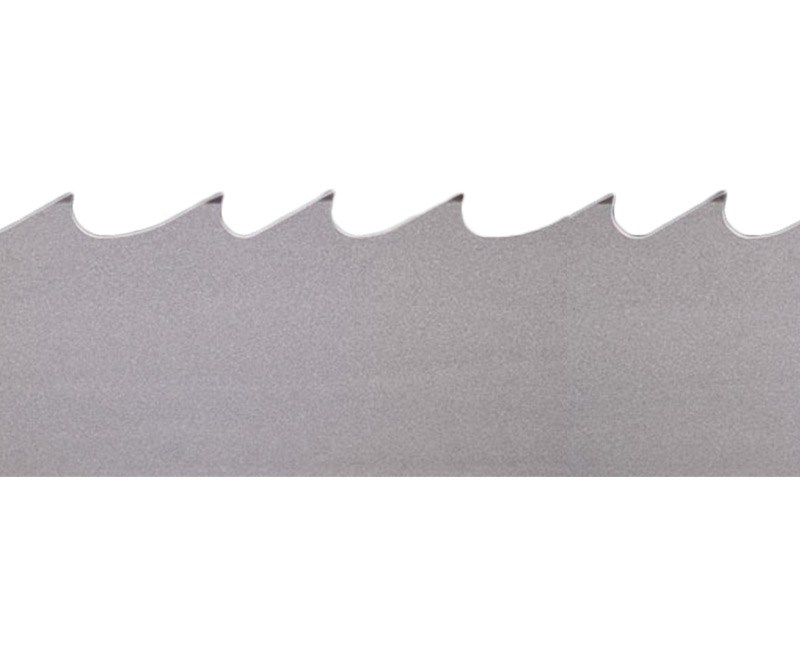

CT Pro

CT Pro

CT-flex Pro

CT-flex Pro is especially engineered for sawing hard-to- cut and abrasive materials.

The particular characteristic of the carbide saw blade CT-flex Pro is the unique tooth

geometry. This is achieved by the tooth setting which enables a maximum free

cutting. The minor vibration development enhances the cutting precision and at the

same time it prevents tooth breakage.

鋸切硬度參考:HRC ≤ 65度

應用範圍: 圓棒材/方形柱/扁鐵/管材

GTX

GTX

duoflex GTX

The bimetal bale duflex GT is designed to cut large to very large work pieces. Due to

its specially ground toothing, this blade is characterized by long blade life and

extremely clean cutting surface.

鋸切硬度參考:HRC ≤ 44度

應用範圍:圓棒材/方柱/扁鐵/工字鋼

PT

PT

duoflex PT

duoflex PT stands for highest cutting performance and blade life in interrupted cuts.

Its special tooth geometry significantly reduces vibration and tooth breakage in

application, such as pipes and tubes.

鋸切硬度參考:HRC ≤ 44度

應用範圍:成捆圓棒材/成捆並列方管材/成捆管材/並列鋸切/厚壁管材/整把角鐵/槽鐵

VTX

VTX

duoflex VTX

This high performance bimetal blade with variable, strongly positive tooth geometry

is engineered particularly for cutting large applications.

The new powder-metallurgical cutting edge featuring a very homogenous micro-

structure performs much better regarding blade life compared to bimetal blades

having a conventional micro-structure. Further significant benefits are reduced

cutting forces thanks to an intelligent chip distribution by a multi-level tooth set.

應用範圍:圓棒材/方柱/扁鋼板

SPX

SPX

douflex SPX

Special materials demand special band saw blades. We developed duoflex® SPX for

high-alloy materials such as Hastelloy, Monel, Nimonic, and austenitic steels. The

optimized tooth geometry equipped with a micro-resistant, stable cutting edge

allows for precise and efficient sawing and long blade life.

鋸切硬度參考:HRC ≤ 49度

應用範圍:厚壁管材/棒材/方柱/扁鐵/工字鋼